TubAirfree® – for sensitive formulas

By combining the airless tube from our partner Pumpart System with the intelligent closure from Gaplast, TubAirfree® offers the best possible protection for your beauty product.

Thanks to the cooperation with our partner Pumpart System from France, we were able to further develop the airless packaging solution TubAirfree®. This makes the metal-free dispensing system suitable for low-viscosity & sensitive formulations and ensures precise dosing.

4 Key Facts about the system:

- Flip cap with integrated valve

- Airless system for 360° usage

- Tube that keeps it shpae

- High restitution rate

Thanks to the high restitution rate of the tube, your high-quality cosmetic product is not wasted, but is used by the consumer down to the last drop. The additional product protection provided by the innovative closure complements the entire system.

The principle

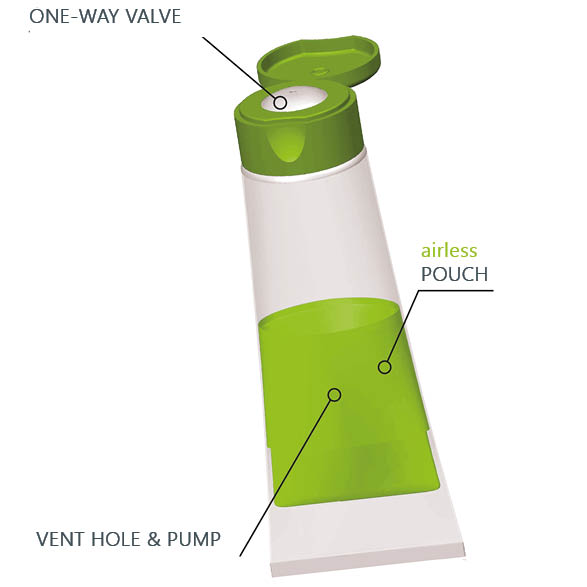

- The inner bag of the airless tube TubAirless® (Pumpart System) contains the sensitive product formulation.

- When the product is dispensed by squeezing the airless tube at the blow hole, the inner bag moves towards the tube neck.

- If you release the vent hole, the space will be ventilated again, and the tube will return to its original state.

Usage

With our long-standing partnership with Pumpart, we are able to offer this complete packaging solution.

TubAirfree® is currently available in the following configurations:

- 35 mm closure with one-way valve from Gaplast

- 50 – 150 ml TubAirless® tube from Pumpart System

Benefits (B2B)

- For sensitive formulations & low viscosities

- Protection against chemical, physical, and microbiological contamination through metal-free airless system

- Additional formulation protection through integrated one-way valve

- Microbiologically tested for PFS Class 1 (Cosmetic Valley Test protocols from 2021)

- High-quality decoration of the tube possible through our network with Pumpart

Benefits (B2C)

- Product fomulas with few to no preservatives

- Real 360° usage

- High restitution rate, hence no product wastage

- Protection of the formulation

- Precise and controlled dosage